Spray foam insulation is a direct countermeasure to ice dams because it stops the root cause: heat loss from your home into the attic. By creating a complete air and thermal barrier on the underside of the roof deck, it keeps the roof surface cold. When the roof stays at or near the outdoor temperature, the snow on top doesn’t melt from underneath. Without melting snow, there’s no water to run down to the eaves and refreeze, which is how an ice dam forms. This approach treats the problem at its source rather than just managing the symptoms.

This article breaks down the science behind how this works, compares it to other spray foam methods, and outlines what you need to know before considering it for your home. The information here comes from extensive field experience in building science and thermal performance.

Ice dams are a product of a simple, destructive cycle. It starts when warm, conditioned air from your living space leaks into the attic. This heat passes through the ceiling, warming the underside of the roof and raising its surface temperature above freezing. The snow on the roof then melts.

As the meltwater runs down the roof, it reaches the cold eaves and gutters, which hang over the unheated edge of the house. Here, the water refreezes, creating a small ledge of ice. As more water flows down, it hits this ledge and freezes, causing the ice dam to grow larger. Water then pools behind the dam, where it can work its way under shingles and leak into the attic and walls, causing significant damage. The Insurance Information Institute notes that water damage from ice dams is a common and costly wintertime claim for homeowners.

The two main culprits that facilitate this process are:

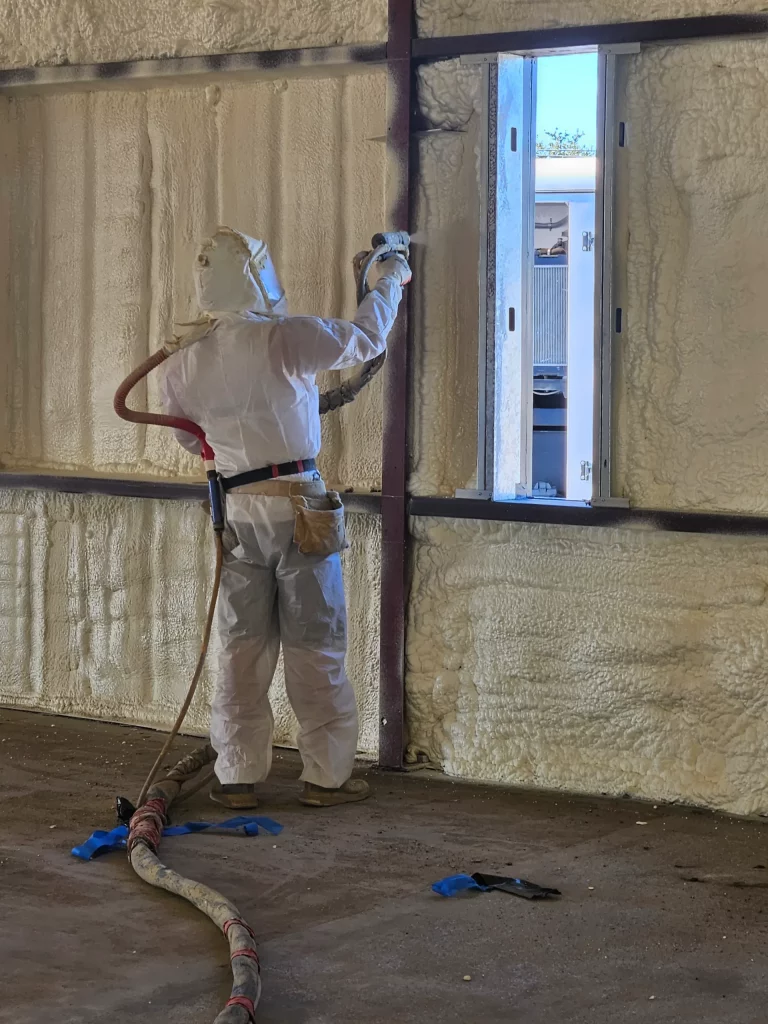

Spray foam insulation tackles both air leakage and heat conduction at the same time. It’s applied as a liquid that expands into a solid foam, adhering directly to the surfaces of your attic.

Unlike traditional insulation materials, which are simply placed in joist cavities, spray foam expands to fill every crack, gap, and penetration. This creates a monolithic, airtight seal. By stopping the convective air currents from your living space, you eliminate the primary source of heat that melts the snow on your roof. This air-sealing quality is arguably its most important feature for preventing ice dams.

Beyond its air-sealing capabilities, spray foam provides a high R-value, which is the measure of thermal resistance. This means it’s highly effective at stopping heat transfer through conduction. A cold roof deck is the goal, and a high R-value is essential to achieving that.

Applying spray foam directly to the underside of the roof deck creates what is known as an unvented or “conditioned” attic. This method brings the attic inside the home’s thermal envelope. The roof deck is no longer exposed to warm attic air, so its temperature remains close to the outside air temperature. An unvented attic is a common and effective strategy in modern building science for managing both temperature and moisture. According to guidance from the U.S. Department of Energy, this approach can be very effective in stopping the formation of ice dams.

Different insulation materials have varying levels of effectiveness when it comes to stopping the heat loss and air leakage that cause ice dams. The table below shows a direct comparison.

| Feature | Spray Foam Insulation | Fiberglass Batts | Blown-in Cellulose |

|---|---|---|---|

| Air Sealing Ability | Excellent (Forms a complete air barrier) | Poor (Air can move freely through and around batts) | Fair (Reduces airflow but does not stop it) |

| Typical R-Value | R-6.0 to R-7.0 per inch (Closed-Cell) | R-3.1 to R-3.8 per inch | R-3.2 to R-3.8 per inch |

| Moisture Resistance | Excellent (Closed-cell acts as a vapor barrier) | Poor (Can absorb moisture and lose R-value) | Fair (Treated to resist moisture but can still absorb it) |

| Ice Dam Prevention | Highly Effective | Low to Moderate Effectiveness | Moderate Effectiveness |

As the comparison shows, while fiberglass and cellulose can provide thermal resistance, they do not create an air barrier. Air can still move through these materials, carrying heat to the roof deck. Spray foam is the only one that provides both in a single application.

Before you move forward with spray foam, there are a few practical factors to think about to ensure it’s the right solution for your home.

Before sealing an attic, a thorough inspection of the roof is necessary. Any existing leaks must be repaired. Applying spray foam to a leaking roof will trap moisture and can lead to structural decay. Also, converting to an unvented attic is a specific building strategy. It changes how your roof system manages temperature and moisture, so it’s important that it’s done correctly.

In regions with heavy snowfall and prolonged freezing temperatures, like the northern United States, a complete air seal and a high R-value are non-negotiable. For these climates, closed-cell spray foam is often the preferred choice due to its higher R-value per inch and its ability to act as a vapor barrier, which helps control moisture from inside the home.

Spray foam insulation is a chemical product that must be installed by trained and certified professionals. The Spray Polyurethane Foam Alliance stresses the importance of hiring qualified contractors who understand the equipment, safety protocols, and building science principles involved. Proper installation is critical for both performance and safety.

Open-cell spray foam is lighter, less dense, and a great air barrier, but it is permeable to vapor. Closed-cell spray foam is dense, provides a higher R-value per inch, and acts as its own vapor barrier. For ice dam prevention in cold climates, closed-cell is often recommended for its structural rigidity and moisture resistance.

Some shingle manufacturers have raised concerns about unvented attics. However, most major manufacturers have approved the use of spray foam when installed according to their guidelines and building codes. It’s best to check with your specific shingle manufacturer for their policy.

When installed properly, spray foam is a durable material that does not sag, settle, or degrade over time. It should last for the life of the building, maintaining its R-value and air-sealing properties without needing replacement.

While spray foam is highly effective at stopping the primary cause of ice dams (heat loss), other factors like attic ventilation (if you choose to keep a vented attic) and gutter maintenance also matter. However, creating a sealed, insulated attic is the most direct and permanent solution.

Answering these common questions highlights that spray foam insulation offers a permanent solution by directly controlling the heat and air movement that cause ice dams. By creating a seamless thermal and air barrier, it keeps the roof surface cold and stops the destructive snow-melt cycle before it can begin.

Before making any changes, it’s a good idea to have your home evaluated to understand its specific points of heat loss. This will help you make an informed decision based on your home’s construction and your long-term goals.

Spray Foam Tech continues to grow, reaching new communities with advanced spray foam applications designed for all climates. Read more about our latest expansion.

If you’re dealing with recurring ice dams, a professional evaluation can identify the sources of heat loss and determine the most effective insulation strategy. For a detailed assessment of your home’s needs, you can contact Spray Foam Tech at (737) 777-9590 or send an email to oldworldtx@hotmail.com to discuss your situation. An expert can provide clarity on the best approach for keeping your home safe and warm this winter.